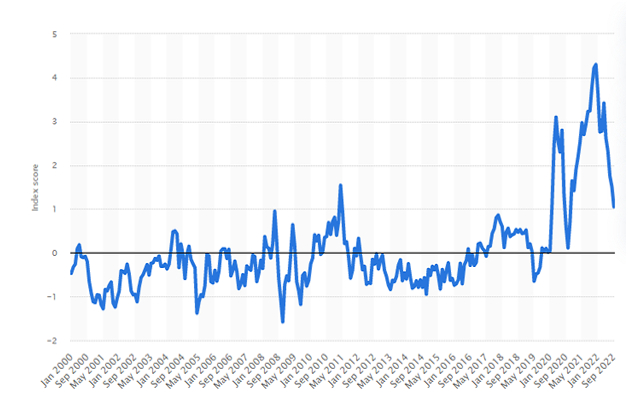

The global supply chain management market stands at a valuation of $19.5 billion. It is expected to grow with a CAGR of 12.17% to reach $34.7 billion by 2027. However, this incremental growth is also met with several challenges. Owing to geo-political and environmental changes, the global supply chain pressure index shows significant spikes.

This results in shortages, delays, and higher costs. It also puts pressure on a global supply chain team to focus on efficiency and resilience to keep up with the challenges. Let’s understand how you can build and manage a global supply chain team to manage operations on an international scale.

3 Crucial Stages for Building and Managing a Global Supply Chain Team

There are four major players in a global supply chain: Suppliers, Manufacturers, Logistics, and Consumers. While three of these are fixed in a region, the role of logistics is to connect them so that inventory can move through the supply chain. The biggest challenge for building a global supply chain team is to identify the key players in different regions and connect the dots with logistics.

In a global supply chain, these players are spread in different countries. Owing to this, there are numerous ways for a company to form a global supply chain. A company can form strategic partnerships with regional players or develop its resources in a region. Let’s understand the various stages of building a global supply chain:

Stage 1. Planning

The planning stage is critical when you are building a global supply chain team. The costs and risks are significantly higher when planning a global supply chain compared to a regional supply chain.

The first step is to identify the existing resources and target markets. Based on the identified gap between these two, you can define the goals for your global supply chain team. These goals will in turn guide your strategy.

The next step is to identify the locations for the necessary supply components to serve the target markets. These components include manufacturing units and distribution centers. Ideally, you want to position the components close to the target market to reduce the cost of international shipping.

However, you also need to consider the variables that affect these components. For instance, manufacturing units depend on a consistent supply of raw materials, equipment, labor, and so on. You need to consider the cost of running a manufacturing unit in a region and compare it with the cost of shipping inventory from your existing units.

Similarly, you will need to consider the advantages and disadvantages of holding different supply chain components in different regions. You will also need to look at various combinations for supply, manufacturing, and logistics to find the most efficient solution to run your global supply chain.

Stage 2. Sourcing

At this stage, you begin developing your global supply chain team. You begin implementing the strategy from the planning stage. You will invest in resources to develop supply chain components in different regions. And you will source vendors to facilitate these components.

For example, you decide to plant a manufacturing unit in a country. You will need to identify suppliers to deliver raw materials, legal assistance to procure permissions and licenses, sources to attract human resources, logistics partners to store and move inventory, and so on.

You also need to consider the geographical, cultural, political, and legal frameworks of different regions when sourcing for a global supply chain team. You need to pick vendors with long-standing experience in the region. At the same time, your supply chain team needs expertise in international coordination.

The health of a global supply chain depends on the cooperation of its components. Each of these components is dependent on one another. At the same time, the components of a global supply chain also serve as a hedge against one another. You should be able to continue the operations or divert your resources in a region even if the supply chain components in another region face a crisis.

You need to consider this aspect when building your global supply chain team. Although it requires more effort for coordination, regionalized components can help you introduce flexibility and risk management in your global supply chain.

Stage 3. Managing Operations

Managing a global supply chain team can be challenging. You need to ensure cooperation and coordination between different regions and time zones. The organization will also need to keep up with regional and global geo-political events that can affect the supply chain. Furthermore, global supply chain teams also need to overcome cultural differences for efficient operations management.

Here are a few best practices for seamless operations management of a global supply chain team:

Enable Communication

A global supply chain team would operate in different time zones. Hence, it is paramount to define protocols for communication and the flow of information between teams in different regions. The exchange of information is critical for efficient supply chain management.

You can leverage digital communication tools, such as video conferencing, instant messaging, and collaboration platforms, to facilitate real-time communication and foster teamwork. You also need to define the channels for different types of communication.

Define and Communicate Goals

While an organization may need to micro-manage a global supply chain team, it is necessary to keep the stakeholders abreast of the outcomes expected from them. You need to clearly communicate strategic objectives, expectations, and targeted metrics with each component of the global supply chain team.

At the same time, you also need to communicate how the performance of each component would affect the others. For example, you need to communicate how a day’s delay in shipping from manufacturing in one region can result in a 3-day delay in order fulfillment in the target market.

Furthermore, goals and objectives for different regions may change from time to time. You can hold periodic meetings to communicate these with each component of the global supply chain.

Encourage Cross-functional Collaboration

A global supply chain team would need to overcome several barriers. These stem from geographical locations, cultural backgrounds, and different time zones. However, you need your global supply chain team to operate as a single unit instead of a collection of components.

It is necessary to foster relationships and collaboration between the components in different regions. This would allow the components to benefit from the skills, knowledge, experience, and expertise of one another.

For example, your logistics team can guide your warehouse management team on ways to package the goods to avoid shipping damages. The receiving team can guide the shipping team about the necessary customs compliance of the importing region.

This form of collaborative work culture can help reduce friction in a global supply chain team. It can also contribute to improving the efficiency of the overall supply chain.

Leverage Technology

You need to leverage technology for several aspects of global supply chain operations. Using software like warehouse management systems (WMS), devices, and equipment can help create a more organized, trackable, and efficient global supply chain team. Here are a few ways technology can help your organization:

● An integrated inventory management system can help you track inventory levels in different regions.

● Tracking devices along with a logistics management system can help you track shipments across the globe in real time.

● Project management tools can help you improve communication and collaboration between different teams.

● You can use global supply chain management tools to manage supply chains based on demand fluctuations in different regions.

● Internet of Things (IoT) devices can help you remotely manage certain operations with little to no human intervention.

●Operations management tools can generate automated alerts to transmit information between different teams.

Leveraging technology for supply chain management can help you create streamlined operations. It can enable collaboration within the global supply chain and reduce the margin of human error. Additionally, introducing technology into your global supply chain team can also help you generate data. This will help you draw insights on performance which can inform your decision-making.

Conclusion

Building and managing a global supply chain team requires you to design and maintain a complex web of components dealing with supply, manufacturing, and logistics. You need to carefully plan your supply chain to strategically position each component to yield the best output.

You also need to manage each component independently and as part of an integrated system. It is necessary to leverage technology to foster collaboration and coordination between the components of your global supply chain team. Most importantly, you need to consider the ever-evolving nature of a global supply chain and manage your operations accordingly.